Body, Bend

A collaboration with Nyokabi Kariuki to build a wearable percussion instrument

Project description:

In 2025 I was commissioned by the Univerität für Musik und Darstellende Künste in Vienna to make a wearable percussion instrument for musician Nyokabi Kariũki. Nyokabi is a Kenyan performer and composer who incorporates African influences into her music, and has a particular interest in body percussion traditions rooted in Kenyan culture and history.

Over three months I prototyped, developed and produced this wearable instrument, using 3D printing, traditional leather techniques, embedded audio and signal processing, and materials innovation. It debuted in Vienna in July 2025.

Role:

Design, fabrication, embedded software development, digital signal processing

Introduction

I met Nyokabi Kyriuki in Nairobi in 2024. She is a force of nature; her music is poetic, rhythmic, and deeply rooted in Kenyan culture.

When I was asked by the Universität für Musik und Darstellende Künste in Vienna to make her a wearable percussion instrument, I was thrilled. I also knew that the material and technical challenges would be enormous.

In the end, I produced a wearable instrument consisting of a chest piece and gloves that integrates with her musical stage setup, perfectly suited to her musical style.

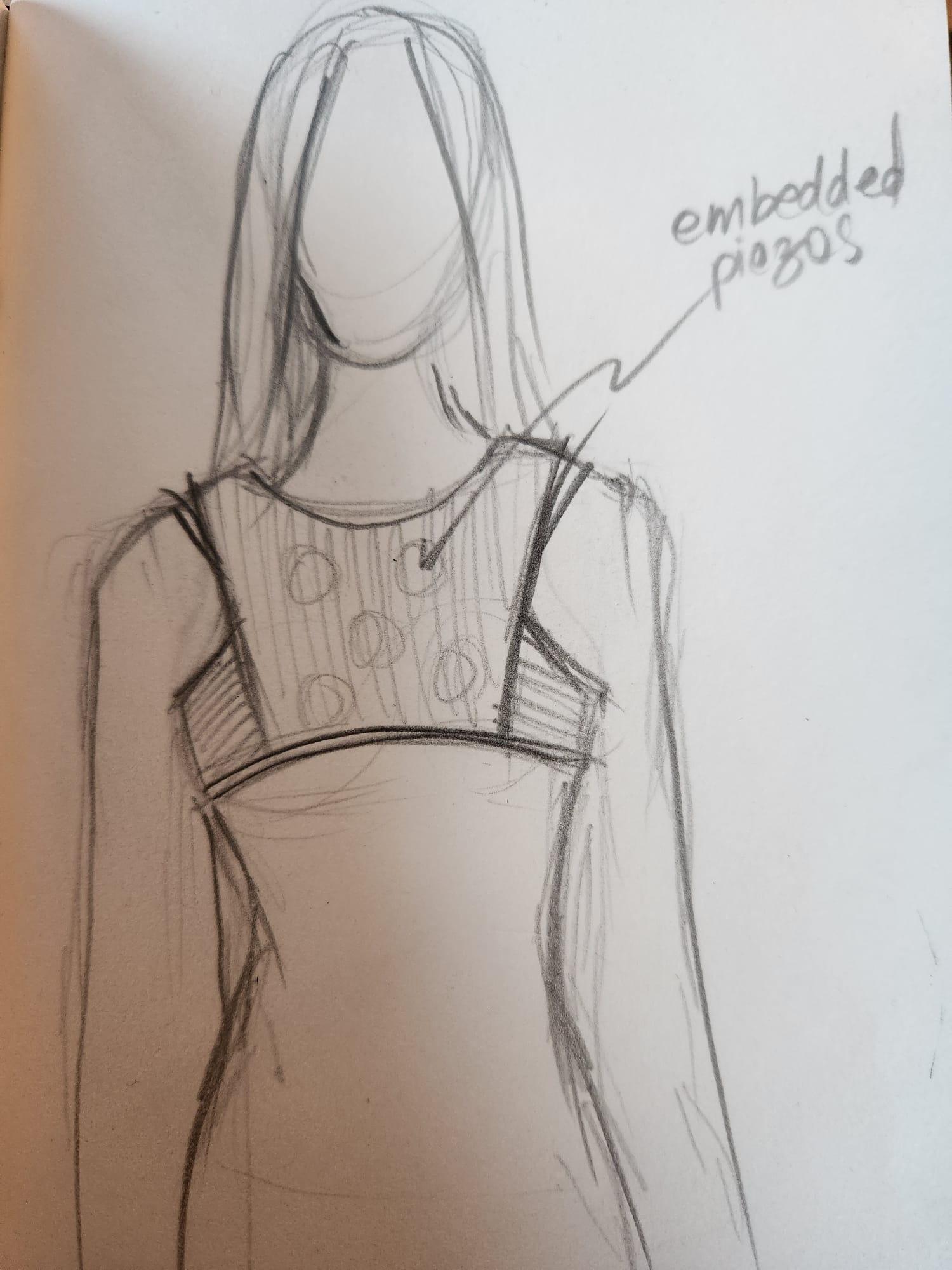

Preliminary sketches

Material challenges

The core challenge was to create something that was light and comfortable enough to wear for an entire performance, robust enough to withstand high-energy movement, responsive enough to capture subtle gestures, and looked really cool.

The basic material of the wearable was a primary concern, because that material, if it's too insulating, can act as a low pass filter for the piezo sensors, which was a particular concern for the chest piece which had a large playable surface area. I found that leather had a really nice response, so I settled on leather as a substrate. I'm lucky enough to live a short distance away from Germany's premiere leather dealer and I went there often over a few weeks, buying scraps of various thicknesses and densities, detemining the right combination of leather that would be comfortable and malleable to make into a chest piece but thin enough to not impede signal response. This ended up being a beautiful, paper-thin black suede that was flecked with gold. For the gloves I found a slightly heavier smooth leather that would provide the stability I needed while being flexible enough to provide the degree of freedom hands require.

The gloves incorporated an array of discreet sensors, enabling Nyokabi to trigger percussive samples, modulate effects, and layer rhythms in real time. Every contact point was mapped to her exact stage setup, so the instrument felt less like a foreign device and more like an extension of her own movement vocabulary.

The result was a piece that blends cultural resonance with cutting-edge design: a sculptural form that speaks to Kenyan craft traditions, yet seamlessly integrates with contemporary performance technology. On stage, it moves with her, catching the light, shaping the sound — not just an instrument, but part of her presence.

Incorporating the sensors

The most challenging problem was integrating piezo sensors into a wearable form without sacrificing stability or signal quality. Piezo discs are my go-to for percussion instruments — they’re inexpensive, capture a beautiful, detailed signal, and I’ve refined techniques for processing them over years of work. But in a soft, moving system like a wearable, even slight movement can produce noise or damage solder joints.

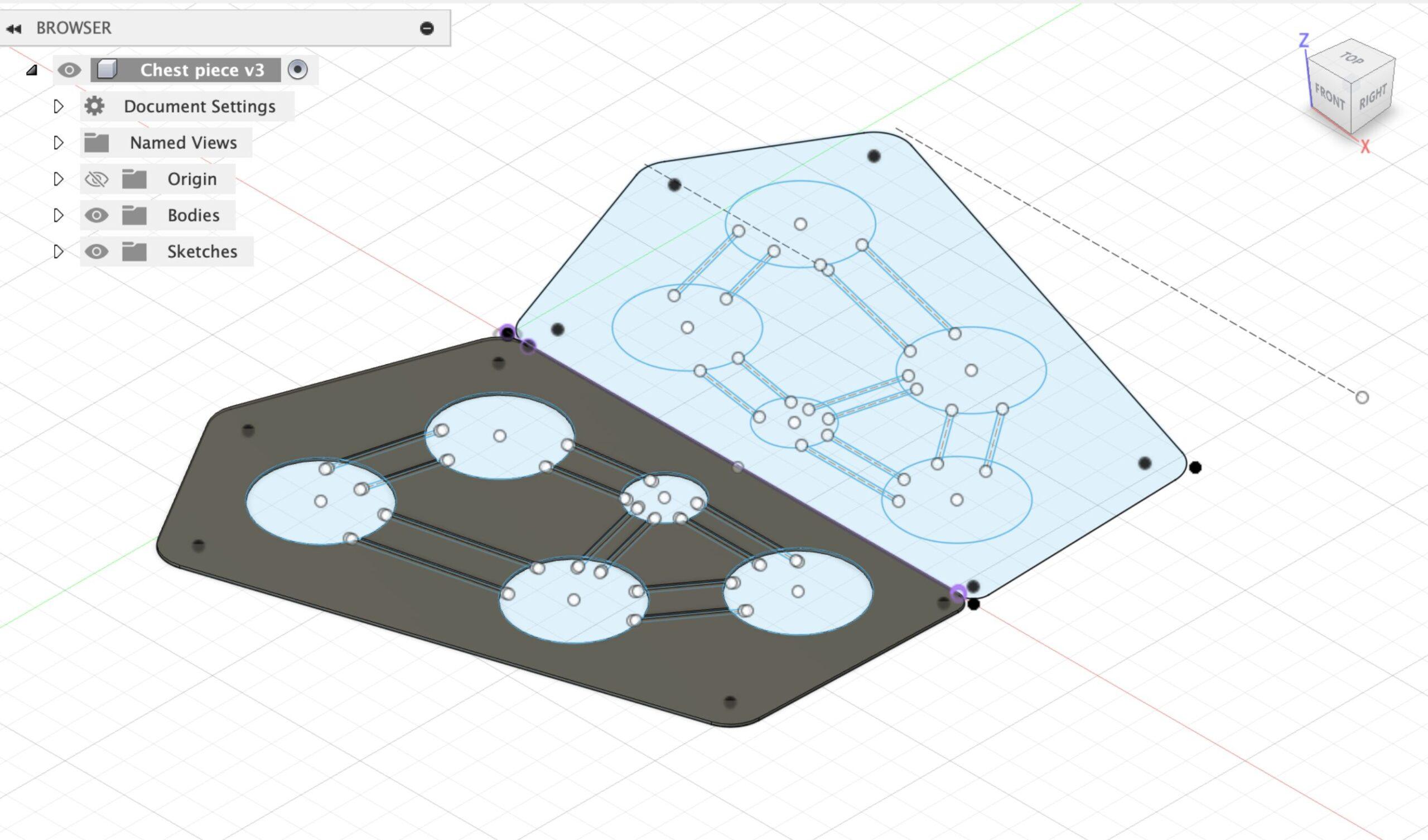

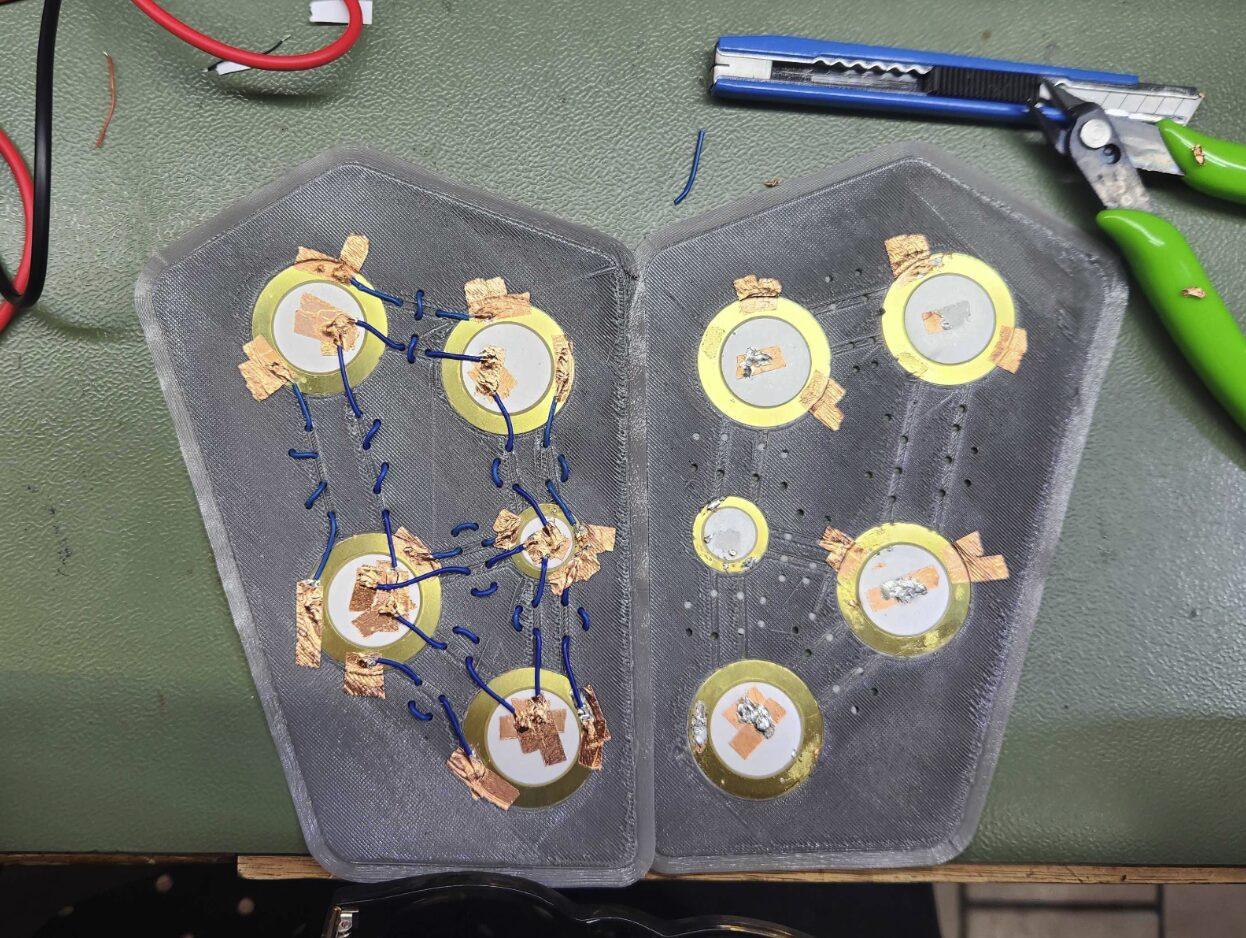

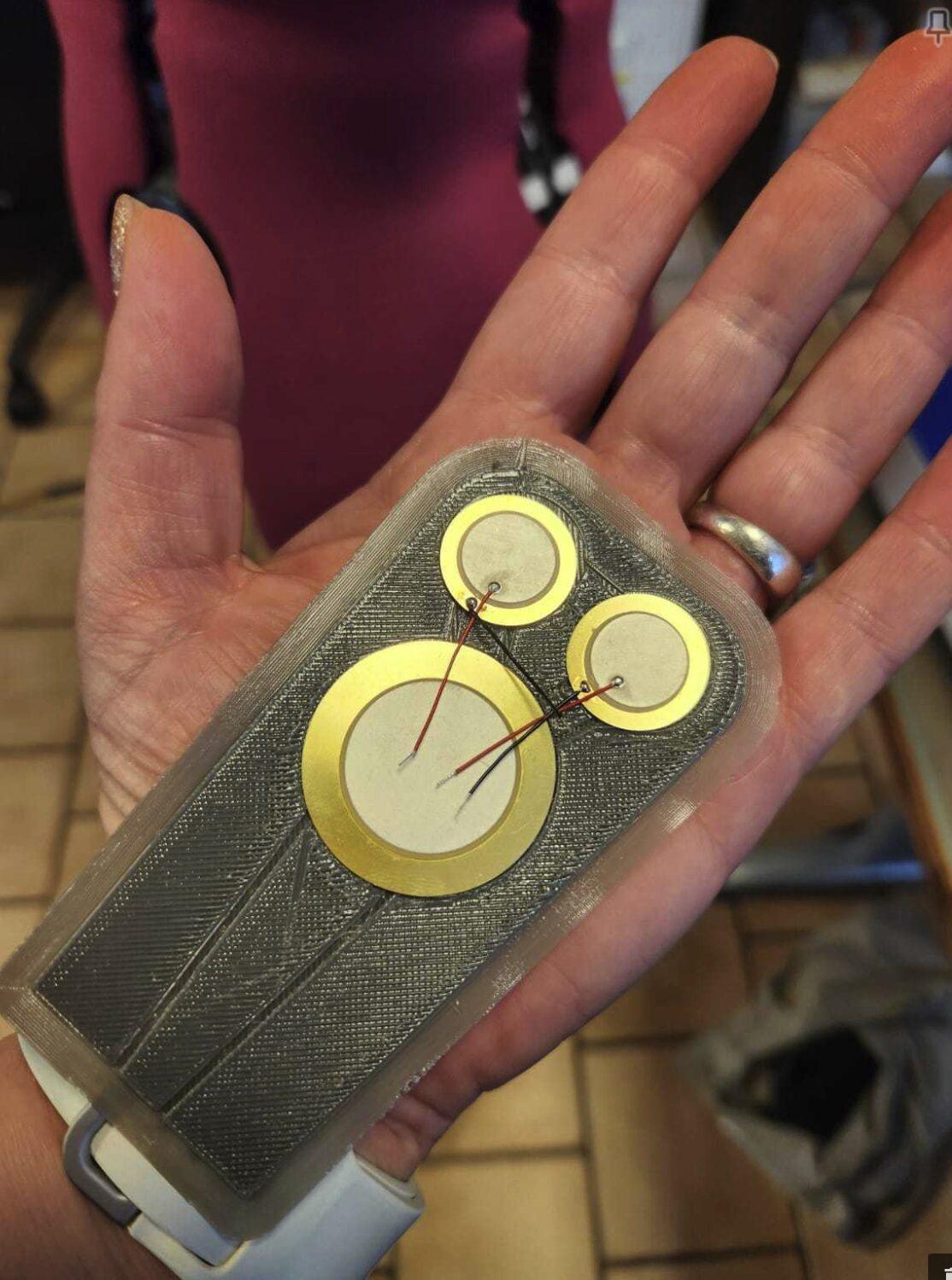

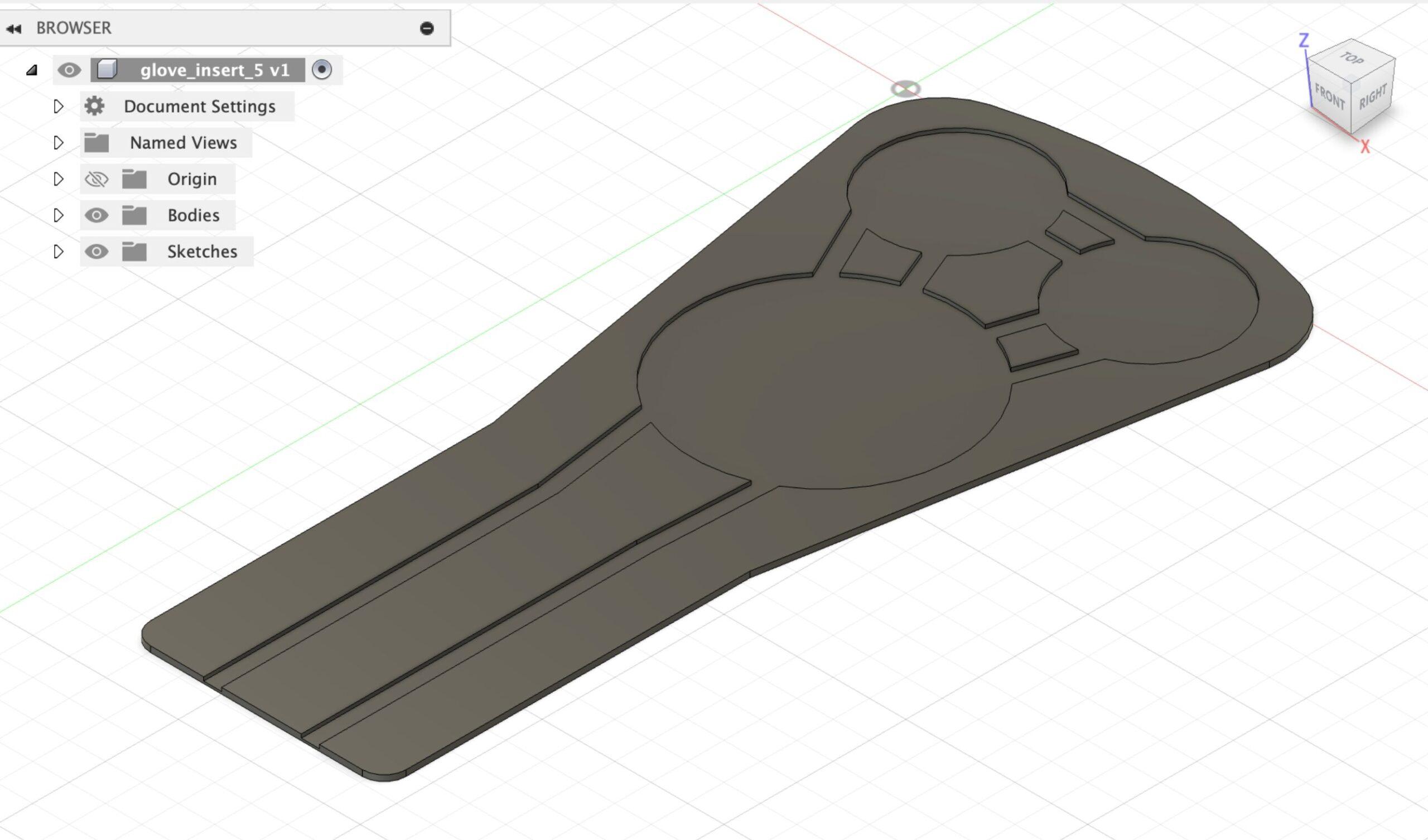

My solution was a custom 3D-printed flexible substrate: thin enough to bend and conform to the curves of the chest and hands, yet rigid enough to hold each sensor firmly in place. I mounted the sensors directly into this substrate, then punched precise holes to weave their connecting wires through. This relieved strain on every solder joint and locked the wiring in place — no shifting, no loose connections.

Every structural component was also custom-made. I printed all connectors, a sculpted back panel to house the central processor, and paired them with a two-layer leather chest piece and wide elastic straps for comfort. The result is a system that’s light, durable, and responsive — one that looks as considered as it sounds.

Fusion drawing of the chest substrate

Chest sensors set into the substrate

Glove sensors in place

Fusion drawing of glove substrate

Weaving in the signal wires to the flexible substrate

Glove configuration, with sensors enclosed in a two-layer glove and stabilised with elastic wrap

The design

I prototyped the chest piece in fake leather to get the shape right and determine how the closures would function. I settled on a cropped shape that was backless, with a strap system to hold it in place.

Fitting, front

Fitting, side

Incorporating the embedded system

I used a Bela Mini with a Multichannel Expander for the central processing in this system. I designed and printed a flexible back plate to act as the collection point for the straps as well as all signals. The Bela Mini snapped into place in a friction-fit mount.

I developed and implemented the signal processing in C++. The Bela Mini system took in the piezo data as three channels of audio, filtered and processed it in real time, and output up to three channels of audio and/or three channels of MIDI that could be mapped to any parameter. I wanted this to be flexible enough so Nyokabi could incorporate the audio and/or the velocity information as MIDI in any part of her setup, to support a wide range of musical applications.

For the premiere in Vienna, the chest piece sent MIDI signals to control playback volume of a boom sample in Ableton Live. The gloves delivered two independent audio channels, allowing for a rich vocabulary of sounds including clapping, tapping, and textural contact.

Video documentation

Nyokabi is currently touring and performing with this instrument. Below is footage of her performing at the Sonic Territories festival in Vienna, October 2025:

Thanks

Thanks to Nyokabi Kariũki for being an inspiring and exciting collaborator on this project, and for sharing her time, input and ideas. Thanks also to Alex Hofman and the MAPPER project at Universität für Musik und darstellende Kunst Wien for funding and supporting this work.

See More